In today’s rapidly evolving energy landscape, home energy storage systems (HESS) have emerged as a crucial component in achieving sustainable and efficient power consumption. As the demand for HESS continues to grow, it is imperative to ensure that these systems meet the highest standards of quality control throughout their logistics process.

Click to find more about home ess.

The Importance of Quality Control in HESS

Quality control plays a vital role in ensuring that HESS products are safe, reliable, and perform optimally. By implementing stringent quality control measures, manufacturers can identify and rectify any potential defects or issues before the systems reach consumers’ homes. This not only enhances customer satisfaction but also safeguards against safety hazards and costly product recalls.

Find more about hybrid inverter factory.

Quality Control Measures at Hybrid Inverter Factories

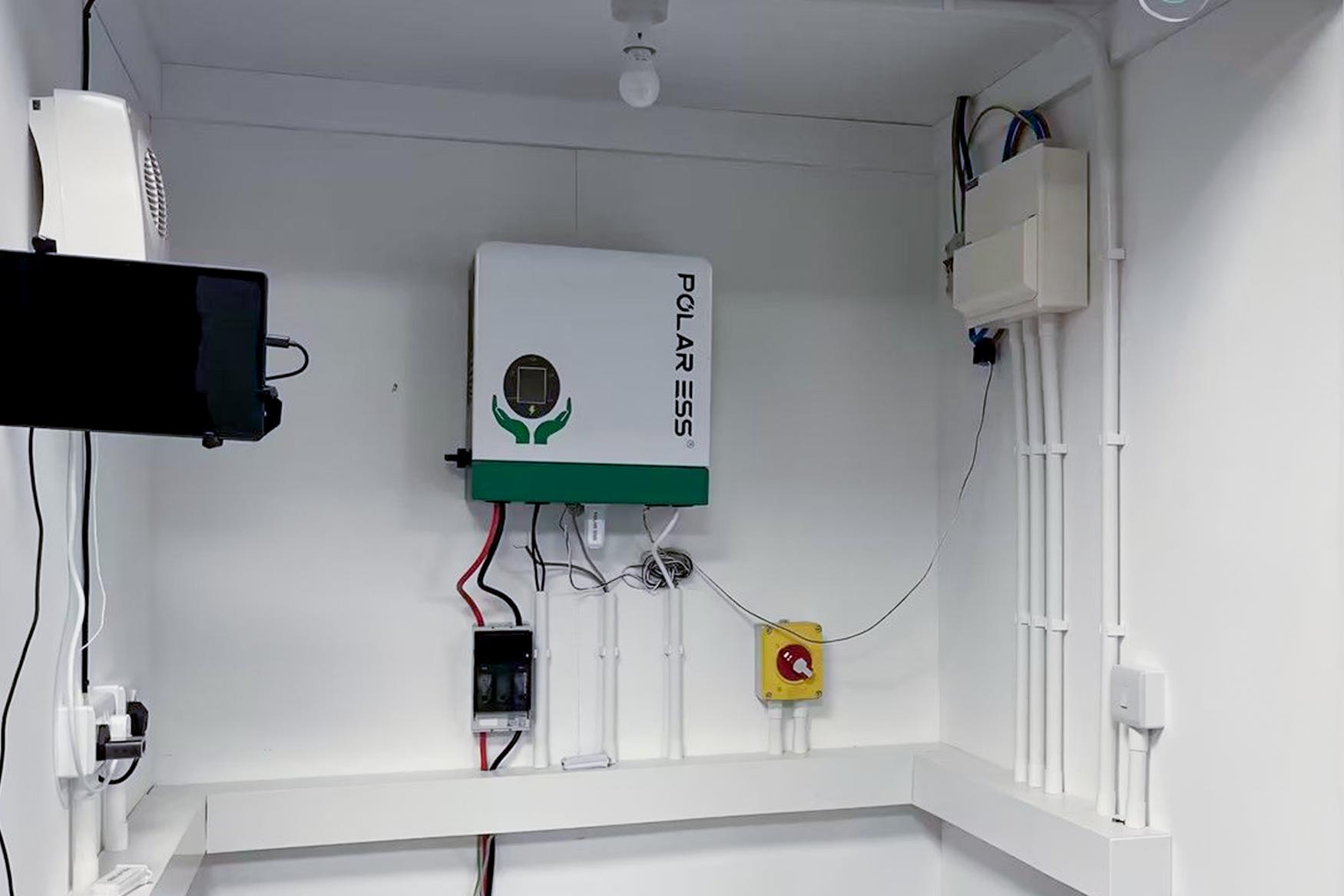

The hybrid inverter is a critical component of HESS as it converts direct current (DC) from solar panels into alternating current (AC) for household use while managing battery charging and discharging. At hybrid inverter factories, rigorous quality control procedures are implemented to guarantee the performance and reliability of these devices.

This includes comprehensive testing protocols where each hybrid inverter undergoes thorough functionality checks under various load conditions. Additionally, advanced diagnostic tools are utilized to detect any anomalies or deviations from specifications during production processes.

Ensuring Quality with Solar Battery Storage

Solar battery storage is an integral part of HESS as it allows homeowners to store excess solar energy generated during the day for later use when sunlight is limited or unavailable. To maintain high-quality standards with solar battery storage units, meticulous quality control practices are employed throughout their logistics journey.

This involves conducting extensive performance tests on individual batteries within controlled environments to assess their capacity retention, cycle life durability, efficiency levels, and safety features. Furthermore, strict monitoring of the manufacturing process ensures that all components are assembled correctly and adhere to industry standards.

Conclusion

In conclusion, quality control is paramount in the logistics of home energy storage systems (HESS). By implementing robust quality control measures at hybrid inverter factories and throughout the solar battery storage production process, manufacturers can ensure that HESS products meet stringent performance, reliability, and safety requirements. This not only enhances customer satisfaction but also contributes to a sustainable and efficient energy future.